Times:2025-11-24 17:15:35

On the precision track of industrial automation, the "purity" and "stability" of signals directly determine the operational accuracy and safety boundary of equipment. In practical applications, traditional optocouplers often face many bottlenecks: sudden drops in response speed under high temperature environments, insufficient anti-interference ability leading to signal distortion, and long-term stability degradation causing equipment misoperation. These problems not only increase operation and maintenance costs, but also may cause serious safety hazards in critical scenarios.

Core technology iteration unlocks new heights in optocoupler performance

The core value of optocouplers lies in "isolation" and "transmission", and the implementation of these two functions relies on the collaborative optimization of light emitting tubes, light receiving tubes, and packaging technology. Otter AT1018 and AT1019 have achieved multiple breakthroughs in core technology, fundamentally improving product stability and adaptability.

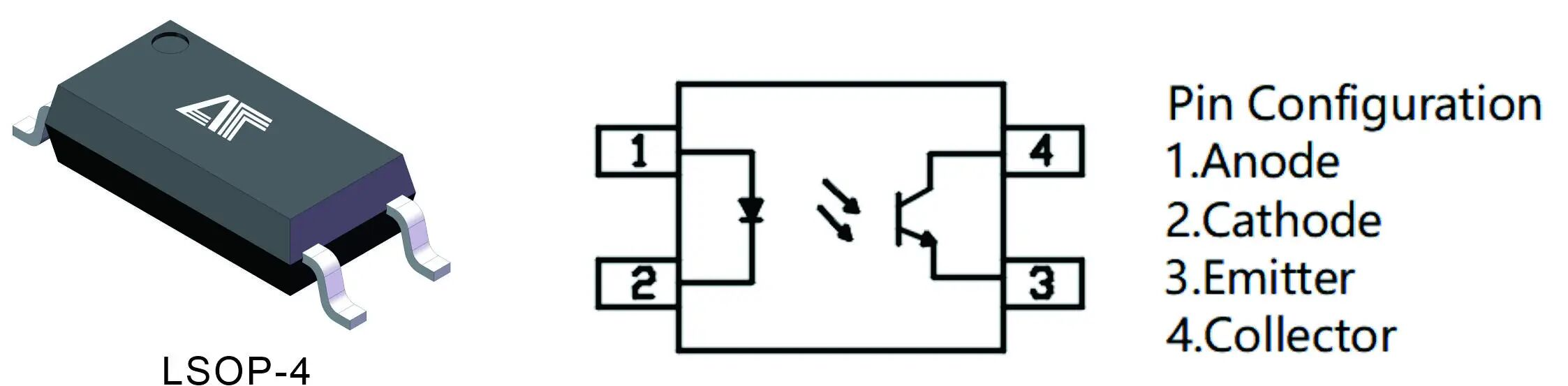

Adopting a 4-pin LSOP4 lead-free chip package, this package not only complies with environmental directives such as EU RoHS, but also significantly reduces the size and weight of the optocoupler. For devices such as PD fast charging chargers and small smart meters that pursue lightweight design, this design can save circuit board space and help terminal products achieve miniaturization and portability.

AT1018/1019 Product Core Advantages

• AT1018(130%~260% CTR):

Its CTR range is 30% higher than the industry's conventional upper limit, and it still maintains stable output under IF=10mA conditions. Taking the industrial PLC digital output module as an example: the traditional optocoupler CTR is less than 80%, and an additional transistor amplification circuit is needed to drive the 10mA level intermediate relay, resulting in a 25% increase in PCB area; And AT1018 can directly drive the relay coil, not only reducing 2 peripheral components, but also reducing the signal transmission delay from 30 μ s to 18 μ s.

• AT1019(200%~400% CTR):

A peak CTR of 400% enables it to output a driving current of 40mA with an input current of 10mA, fully meeting the requirements of heavy loads such as dual MOSFETs. In the 140W PD fast charging scheme, traditional optocouplers require a two-stage amplifier circuit to drive, resulting in an efficiency loss of 5%; After adopting AT1019, it can be directly driven, and the charging efficiency is improved to over 96%.

Super isolation and wide temperature range

The input and output isolation voltages of both optocouplers reach 5000Vrms, and with an 8mm creepage distance, they can efficiently isolate high and low voltage circuits, avoiding damage to sensitive components caused by high voltage impact; Working temperature range -55 ℃~+110 ℃, whether it is industrial equipment in cold outdoor environments or internal circuits of household appliances operating at high temperatures, it can work stably without performance degradation due to temperature fluctuations, and is suitable for harsh working conditions in multiple scenarios.

Strong compatibility and sufficient security

High universal adaptability: compatible with mainstream optocouplers such as Yiguang EL1018, it can directly replace related components without significantly modifying circuit design, reducing the cost of equipment upgrades and component replacements. At the same time, it can adapt to the circuit requirements of various devices such as programmable controllers, switching power supplies, and household appliances.

Application scenarios: From fast charging to full coverage of industrial control

1. PD fast charging (20W-140W)

Pain point: High power fast charging requires driving multiple MOSFETs, and insufficient CTR of traditional optocouplers leads to signal distortion.

Solution: AT1019 directly drives dual MOSFETs, simplifies feedback circuits, and improves charging efficiency by 3% to 5%.

2. Industrial PLC (Programmable Logic Controller)

Pain point: Mixed digital input/output signals and high temperature drift can easily trigger errors.

Solution: The wide temperature characteristic and fast response of AT1018 enable signal transmission error to be less than 0.1ms

3. White goods

Pain point: Due to limited motherboard space, miniaturization and high driver are required.

Solution: AT1018 is compatible with air conditioning thyristor drive, and AT1019 is compatible with water heater relay drive.

AOTE Quality: Building Core Competitiveness through Technological Innovation

As a high-tech enterprise specializing in the research and production of optocouplers, photoelectric sensors, and other products, Autotech has a research and development team composed of multiple industry experts, equipped with advanced photoelectric device testing equipment and production lines. From raw material procurement to product delivery, we have established a full process quality control system.

R&D process

Aote always takes market demand as the guide and conducts customized technology research and development for different industries' application pain points.

Quality Management

Aote has always adhered to the management philosophy of "quality first", striving for excellence, and achieving the goal of "not accepting, not manufacturing, and not exporting" defective products

after-sales service

Whether users encounter problems during product selection or usage, they can receive timely and professional solutions, which is also one of the important reasons why Autotech Electronics can win the trust of users.